Polymer Day 2023 showcases interdisciplinary innovation

Chemical “upcycling,” or converting plastics into higher-value products, to the left. Materials that repair damage and restore themselves to the right. Straight ahead: fibers that can be woven into fabrics and used as microphones or loudspeakers.

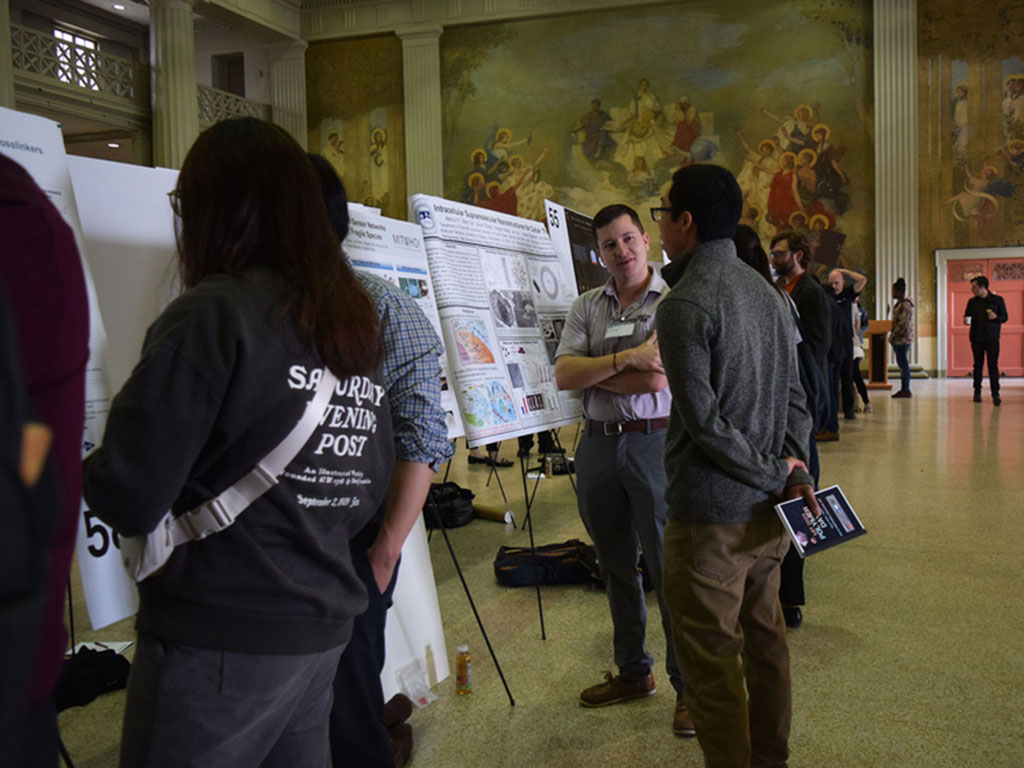

Such was the varied innovation that crowded MIT’s Morss Hall on Polymer Day 2023. Sixty-four teams from schools throughout the Northeast and beyond presented research ahead of a poster contest — the most since the event started in 2013.

“We were almost running out of space in Morss Hall,” says Eric Lee, a graduate student in the MIT’s Department of Materials Science and Engineering and the Program for Polymers and Soft Matter (PPSM), which hosted the event. Lee led the Polymer Day organizing committee along with fellow graduate students Yehlin Cho, Emily Krucker-Velasquez, and Camille Cunin. “We’ve never had this problem before, because there have never been so many participants.”

Polymers are a huge class of materials made of long, repeating chains of molecules. Polymers can be found in a range of applications, from food products to pharmaceuticals — polyethylene in packaging, for example, and the polyester in clothing.

The MIT event included workshops, student seminars, and an alumni career panel. There were also industry booths featuring the 10 sponsors — companies that included Cabot, Dow, and Saint Gobain — also a record number. The purpose of the annual event is to provide students with network opportunities and an avenue to share their research with people in their field, says Lee. It’s also to show the enormous diversity of polymer research.

“That’s what makes it really special,” says Lee. “The coolest thing about PPSM, and polymer science in general, is that it is so interdisciplinary. PPSM brings together chemical engineering, chemistry, materials science, mechanical engineering, and biological engineering. So five different departments.”

Mucus models

That diversity was represented in the research displayed during the day’s poster session. Nadia Zaragoza spoke about her work formulating a synthetic vaginal mucus out of bottlebrush polymers, which, in a microscope, look like the long brushes used to clean glassware.

“I love mucus,” says Zaragoza, a graduate student in DMSE and PPSM. “It’s a very fun material.”

Her end goal is to facilitate better studies of infections such as bacterial vaginosis, a vaginal inflammation caused by an overgrowth of bacteria. It’s a common diagnosis that’s not widely understood.

“We really don’t understand how it happens,” Zaragoza says. “We know that mucus plays a role. So if we could create better vaginal mucus models, could we then study those diseases better?”

Polymers to proteins

Another presenter interested in polymers and health science was Kayla Koch, a grad student in the University of Massachusetts Amherst’s Department of Polymer Science and Engineering. Koch is using polymers to mimic protein transduction domains, also known as cell-penetrating peptides, which can carry antibodies or proteins across the cell membrane into a cell, much like the mRNA vaccine against Covid-19. The vaccine works by delivering mRNA into cells of the body.

“The advantage of using polymers is you can easily tune them. If you wanted to modify the structure of a peptide, it’s a very laborious and taxing process,” says Koch. “With polymer chemistry, you just put everything together and you go.”

Now Koch and her team are trying to optimize polymers to effectively carry proteins across the cell membrane with the aim of delivering therapeutic agents such as drugs. The work she presented at Polymer Day showed what happened when she added different types of alcohol to the polymers.

“We see that it does affect protein delivery. In some cases, it enhances protein delivery,” she said.

Long-lasting bubbles

Saurabh Nath, a postdoc in MIT’s Department of Mechanical Engineering with the Varanasi Research Group, presented his work on bubbles — specifically, on how to make them last. Try to blow bubbles in water, he challenged — they pop in milliseconds.

“The only way you can stabilize them is by adding soap or additives. But once you add soap to water, it's not water anymore — it’s soapy water,” Nath says.

So his study asked simple question: How do you make an air bubble stay a bubble without altering its purity? They tried answering the question by putting silicon oil in a beaker and the beaker on a hot plate. Poking at the oil created bubbles that lasted for about 10 milliseconds. Heat the oil, though, to 68 degrees Celsius (154 degrees Fahrenheit), and bubbles will keep for almost an hour.

The reason: The heat pushes a flow of liquid to the top of the bubble; cooler liquid flows down. “The bubble lives because gravity is counteracted by the flow happening upwards,” Nath says.

One application such knowledge could lead to is foam. Foams — which can be used in insulation, packaging, and safety, among other applications — rely on additives or polymers to give them their structure. Nath described a new kind of foam consisting of a series of long-lasting bubbles, stabilized without any additives whatsoever. Such a material could also solve the problem of “defoaming,” or removing foam when it’s no longer needed.

“This is quite a radical step in the making and breaking of foam,” says Nath. “You switch off the temperature, the bubbles are gone.”

The first-place winner of the poster contest was Joon Ho Park, a postdoc in MIT’s Department of Chemical Engineering, for his presentation “Development of Cartilage Penetrating Dendrimer for Osteoarthritis Treatment.” Topics winning second- and third-place prizes included nature-inspired materials design, data-driven predictions of materials properties, and using DNA as a building block for biomaterials.