Today's Annoyances, Tomorrow's Technology

Paper wrinkles, tape tears, cables kink, columns buckle, eggshells break. Pedro M. Reis hopes to transform today’s annoyances into tomorrow’s technology.

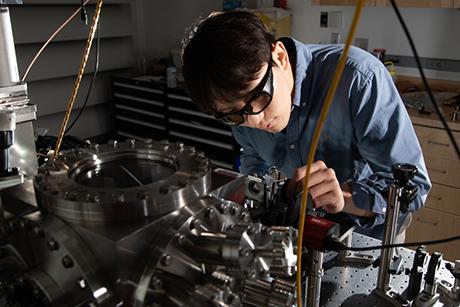

Reis, who holds a dual appointment in mechanical engineering and civil and environmental engineering and recently named one of Popular Science’s “Brilliant Ten,” explores the mechanics and physics underlying natural and manufactured structures with the goal of identifying, classifying, and predicting the ways thin objects deform — and using that knowledge to solve other engineering problems.

Photo: Len Rubenstein

In the engineering world, material failure through buckling or fracture can be merely annoying or completely catastrophic. Reis seeks to exploit apparent weaknesses in different realms. “In our lab we do science-enabled engineering coupled with engineering-motivated science,” he said, “and we try to turn failure into functionality.”

Working with objects in which one dimension is smaller than the other — hair, rods, pipes, paper, plates, shells — Reis pursues “curiosity-based research” at the interface of science and engineering. “The ultimate goal is to discover, understand, and harvest mechanical instabilities in soft mechanical structures,” he says, “and then exploit those as novel functionalities over a wide range of length scales.”

Hence the device he dubbed the Elastopipette, a petal-shaped sheet inspired by floating flowers that grabs and holds water droplets. And the rubbery self-foldable Buckliball with its intricately strutted structure, which, when squeezed, collapses on itself in a predictable way. Besides illuminating a fascinating phenomenon in its own right, the Buckliball can be used to encapsulate miniscule things, but it has also attracted the attention of a nuclear engineer who thinks it might be just the thing for the next generation of particle detectors.

As a teenager, Reis decided to become a physicist after meeting a couple of physics graduate students at a cousin’s wedding. If he had met a NASA scientist that day he might have ended up wanting to be an astronaut, he joked, but his fascination with the confounding tendencies of thin materials can be traced to a distinctly outmoded technology: the compact disc.

Unlike the unpredictable result of a drinking glass or a porcelain plate encountering a tile floor, the packaging film of a CD case, when opened, tears in a regular, visually arresting, almost poetic fashion, creating a fan of delicate sine waves. Reis wondered why.

Now, in his lab, at one bench researchers analyze what looks like an undulating strand of green spaghetti falling onto a treadmill; at the next is a tank filled with water. The first experiment relates to the laying of kilometers-long communication cables onto the seabed; the next explores how a bacterium propels itself with its whip-like tail. What they have in common is the structures are slender and their mechanics are scalable.

The resulting knowledge can be applied to stretchable electronic components, 3-D printing, microfabrication of ultra-thin carbon nanotubes and graphene, or problems encountered by wellbore drilling or kinked transoceanic pipelines, to name a few. Understanding why scotch tape tends to tear in a certain way led to a new way to fabricate tapered graphene nanoribbons. Illuminating the delamination of adhesive films is informing the design and layout of components in novel stretchable electronics devices. Reis’s lab found that the pattern of wrinkles in drapes is identical to that of wrinkled ultra-thin films such as graphene.

“There’s nothing like playing in the lab,” Reis said. “When you play with things, you can discover new things. There’s always a surprise around the corner” that might help turn a sow’s ear into a high-tech version of a silk purse.