Manufacturing a cleaner future

Manufacturing had a big summer. The CHIPS and Science Act, signed into law in August, represents a massive investment in US domestic manufacturing. The Act aims to drastically expand the US semiconductor industry, strengthensupply chains, and invest in R&D for new technological breakthroughs. According to John Hart, professor of mechanical engineering and director of the Laboratory for Manufacturing and Productivity at MIT, the CHIPS Act is just the latest example of significantly increased interest in manufacturing in recent years.

“You have multiple forces working together: reflections from the pandemic’s impact on supply chains, the geopolitical situation around the world, and the urgency and importance of sustainability,”says Hart. “This has now aligned incentives among government, industry, and the investment community to accelerate innovation in manufacturing and industrial technology.”

Hand in hand with this increased focus on manufacturing is a need to prioritize sustainability.

Roughly one-quarter of greenhouse gas emissions came from industry and manufacturing in 2020. Factories and plants can also deplete local water reserves and generate vast amounts of waste, some of which can be toxic.

To address these issues and drive the transition to a low-carbon economy, new products and industrial processes must be developed alongside sustainable manufacturing technologies. Hart sees mechanical engineers as playing a crucial role in this transition.

“Mechanical engineers can uniquely solve critical problems that require next generation hardware technologies, and know how to bring their solutions to scale,” says Hart.

Several fast-growing companies founded by faculty and alumni from MIT’s Department of Mechanical Engineering offer solutions for manufacturing’ environmental problem, paving the path for a more sustainable future.

Gradiant: Cleantech water solutions

Manufacturing requires water, and lots of it. A medium-sized semiconductor fabrication plant uses upwards of 10 million gallons of water a day. In a world increasingly plagued by droughts, this dependence on water poses a major challenge.

Gradiant offers a solution to this water problem. Co-founded by Anurag Bajpayee SM ’08 PhD ’12 and Prakash Govindan PhD ’12, the company is a pioneer in sustainable – or “cleantech” – water projects.

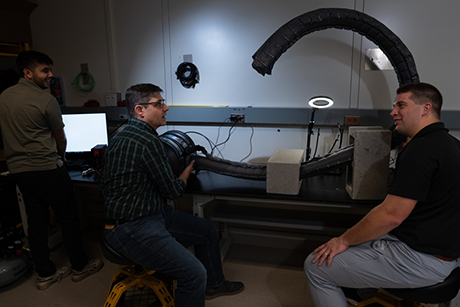

As doctoral students in the Rohsenow Kendall Heat Transfer Laboratory, Bajpayee and Govindan shared a pragmatism and penchant for action. They both worked on desalination research – Bajpayee with Professor Gang Chen and Govindan with Professor John Lienhard.

Inspired by a childhood spent during a severe drought in Chennai, India, Govindan developed a humidification dehumidification technology that mimicked natural rainfall cycles for his PhD. It was with this piece of technology, which they named Carrier Gas Extraction (CGE), that the duo founded Gradiant in 2013.

The key to CGE lies in a proprietary algorithm that accounts for variability in the quality and quantity in wastewater feed. At the heart of the algorithm is a non-dimensional number, which Govindan proposes one day be called the “Lienhard Number,” after his doctoral advisor.

“When the water quality varies in the system, our technology automatically sends a signal to motors within the plant to adjust the flow rates to bring back the non-dimensional number to a value of one. Once it’s brought back to a value of one, you’re running in optimal condition,” explains Govindan, who serves as COO of Gradiant.

This system can treat and clean the wastewater produced by a manufacturing plant for reuse, ultimately conserving millions of gallons of water each year.

As the company has grown, the Gradiant team has added new technologies to their arsenal, including Selective Contaminant Extraction, a cost-efficient method that removes only specific contaminants, and a brine-concentration method called Counter-Flow Reverse Osmosis. They now offer a full technology stack of water and wastewater treatment solutions to clients in industries including pharmaceuticals, energy, mining, food and beverage, and the ever-growing semiconductor industry.

“We are an end-to-end water solutions provider. We have a portfolio of proprietary technologies and will pick and choose from our ‘quiver’ depending on a customer’s needs,” says Bajpayee, who serves as CEO of Gradiant. “Customers look at us as their water partner. We can take care of their water problem end-to-end so they can focus on their core business.”

Gradiant has seen explosive growth over the past decade. With 450 water and wastewater treatment plants built to date, they treat the equivalent of 5 million households’ worth of water each day. Recent acquisitions saw their total employees rise to above 500.

The diversity of Gradiant’s solutions is reflected in their clients, who include Pfizer, AB InBev, and Coca-Cola. They also count semiconductor giants like Micron Technology, GlobalFoundries, Intel, and TSMC among their customers.

“Over the last few years, we have really developed our capabilities and reputation serving semiconductor wastewater and semiconductor ultra-pure water,” says Bajpayee.

Semiconductor manufacturers require ultra-pure water for fabrication. Unlike drinking water, which has a total dissolved solids range in the parts per million, water used to manufacture microchips has a range in the parts per billion or quadrillion.

Currently, the average recycling rate at semiconductor fabrication plants – or fabs – in Singapore is only 43%. Using Gradiant’s technologies, these fabs can recycle 98-to-99% of the 10 million gallons of water they require daily. This reused water is pure enough to be put back into the manufacturing process.

“What we’ve done is eliminated the discharge of this contaminated water and nearly eliminated the dependence of the semiconductor fab on the public water supply,” adds Bajpayee.

With new regulations being introduced, pressure is increasing for fabs to improve their water use, making sustainability even more important to brand owners and their stakeholders.

As the domestic semiconductor industry expands in light of the CHIPS and Science Act, Gradiant sees an opportunity to bring their semiconductor water treatment technologies to more factories in the US.

Via Separations: Efficient chemical filtration

Like Bajpayee and Govindan, Shreya Dave ’09 SM ’12 PhD ’16 focused on desalination for her doctoral thesis. Under the guidance of her advisor Jeffrey Grossman, professor of materials science and engineering, Dave built a membrane that could enable more efficient and cheaper desalination.

A thorough cost and market analysis brought Dave to the conclusion that the desalination membrane she developed would not make it to commercialization.

“The current technologies are just really good at what they do. They’re low cost, mass produced, and they worked. There was no room in the market for ourtechnology,” says Dave.

Shortly after defending her thesis, she read a commentary article in the journal Nature that changed everything. The article outlined a problem. Chemical separations that are central to many manufacturing processes require a huge amount of energy. Industry needed more efficient and cheaper membranes. Dave thought she might have a solution.

After determining there was an economic opportunity, Dave, Grossman, and Brent Keller PhD ’16 founded Via Separations in 2017. Shortly thereafter, they were chosen as one of the first companies to receive funding from MIT’s venture firm, The Engine.

Currently, industrial filtration is done by heating chemicals at very high temperatures to separate compounds. Dave likens it to making pasta by boiling all of the water off until it evaporates and all you are left with is the pasta noodles. In manufacturing, this method of chemical separation is extremely energy intensive and inefficient.

Via Separations has created the chemical equivalent of a “pasta strainer.” Rather than using heat to separate, their membranes “strain” chemical compounds. This method of chemical filtration uses 90% less energy than standard methods.

While most membranes are made of polymers, Via Separations’ membranes are made with graphene-oxide, which can withstand high temperatures and harsh conditions. The membrane is calibrated to the customer’s needs by altering the pore size and tuning the surface chemistry.

Currently, Dave and her team are focusing on the pulp and paper industry as their beachhead market. They have developed a system that makes the recovery of a substance known as “black liquor” more energy efficient.

“When tree becomes paper, only one third of the biomass is used for the paper. Currently the most valuable use for the remaining two thirds not needed for paper is to take it from a pretty dilute stream to a pretty concentrated stream using evaporators by boiling off the water,” says Dave.

This black liquor is then burned. Most of the resulting energy is used to power the filtration process.

“This closed loop system accounts for an enormous amount of energy consumption in the US. We can make that process 84% more efficient by putting the ‘pasta strainer’ in front of the boiler,” adds Dave.

VulcanForms: Additive manufacturing at industrial scale

The first semester John Hart taught at MIT was a fruitful one. He taught a course on 3D printing, broadly known as additive manufacturing (AM). While it wasn’t his main research focus at the time, he found the topic fascinating. So did many of the students in the class, including Martin Feldmann MEng ’14.

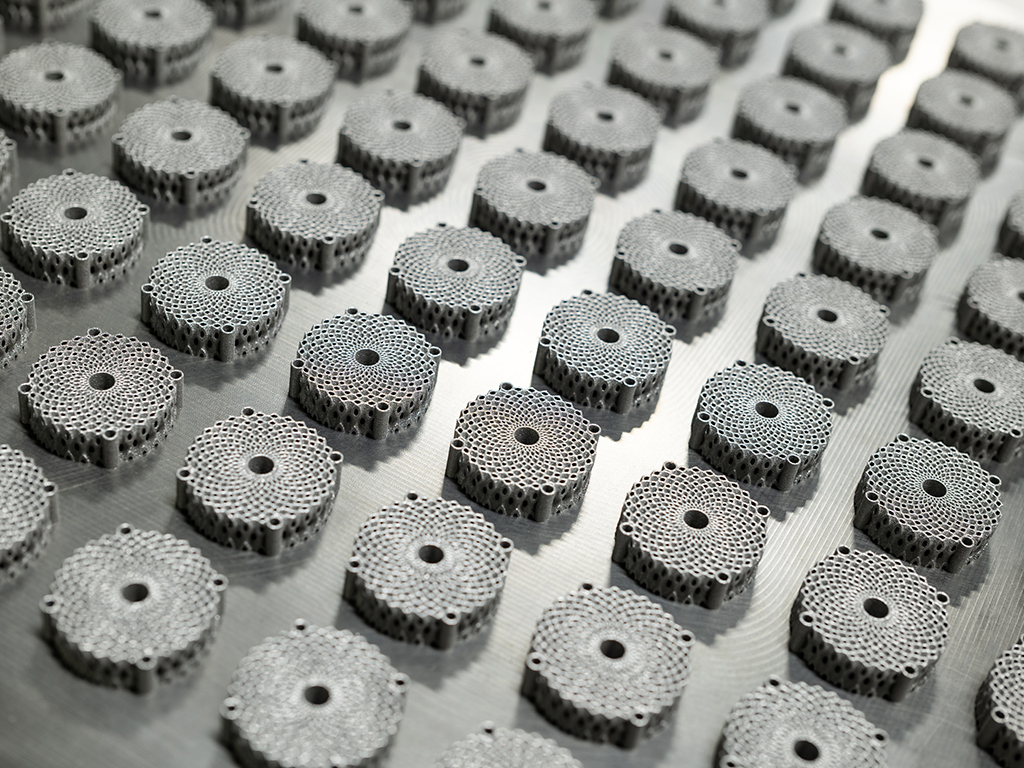

After graduating with his MEng in Advanced Manufacturing, Feldmann joined Hart’s research group full time. There, they bonded over their shared interest in AM. They saw an opportunity to innovate with an established metal AM technology, known as laser powder bed fusion, and came up with a concept to realize metal AM at an industrial scale.

The pair co-founded VulcanForms in 2015.

“We have developed a machine architecture for metal AM that can build parts with exceptional quality and productivity,” says Hart. “And, we have integrated our machines in a fully digital production system, combining AM, post- processing, and precision machining.”

Unlike other companies that sell 3D printers for others to produce parts, VulcanForms makes and sells parts for their customers using their fleet of industrial machines. VulcanForms has grown to nearly 400 employees. Last year, the team opened their first production factory, known as “VulcanOne,” in Devens, Massachusetts.

The quality and precision with which VulcanForms produces parts is critical for products like medical implants, heat exchangers, and aircraft engines. Their machines can print layers of metal thinner than a human hair.

“We’re producing components that are difficult, or in some cases impossible to manufacture otherwise,” adds Hart, who sits on the company’s board of directors.

The technologies developed at VulcanForms may help lead to a more sustainable way to manufacture parts and products, both directly through the additive process and indirectly through more efficient, agile supply chains.

One way that VulcanForms, and AM in general, promotes sustainability is through material savings.

Many of the materials VulcanForms uses, such as titanium alloys, require a great deal of energy to produce. When titanium parts are 3D printed, substantially less of the material is used than in a traditional machining process. This material efficiency is where Hart sees AM making a large impact in terms of energy savings.

Hart also points out that AM can accelerate innovation in clean energy technologies, ranging from more efficient jet engines to future fusion reactors.

“Companies seeking to de-risk and scale clean energy technologies require know-how and access to advanced manufacturing capability, and industrial additive manufacturing is transformative in this regard,” Hart adds.

LiquiGlide: Reducing waste by removing friction

There is an unlikely culprit when it comes to waste in manufacturing and consumer products: friction. Kripa Varanasi, professor of mechanical engineering, and the team at LiquiGlide are on a mission to create a frictionless future, and substantially reduce waste in the process.

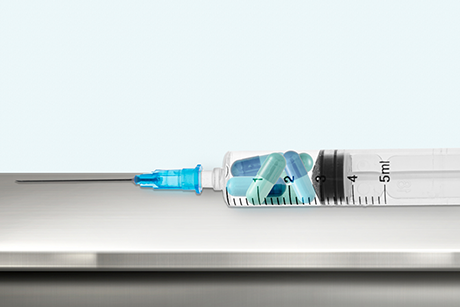

Founded in 2012 by Varanasi and alum David Smith SM ’11, LiquiGlide designs custom coatings that enable liquids to “glide” on surfaces. Every last drop of a product can be used, whether it’s being squeezed out of a tube of toothpaste or drained from a 500 liter tank at a manufacturing plant. Making containers frictionless substantially minimizes wasted product, and eliminates the need to clean a container before recycling or reusing.

Since launching, the company has found great success in consumer products. Customer Colgate utilized LiquiGlide’s technologies in the design of the Colgate Elixir toothpaste bottle, which has been honored with several industry awards for design. In a collaboration with world- renown designer Yves Béhar, LiquiGlide is applying their technology to beauty and personal care product packaging. Meanwhile, the FDA has granted them a Device Master Filing, opening up opportunities for the technology to be used in medical devices, drug delivery, and biopharmaceuticals.

In 2016, the company developed a system to make manufacturing containers frictionless. Called CleanTanX, the technology is used to treat the surfaces of tanks, funnels, and hoppers, preventing materials from sticking to the side. The system can reduce material waste by up to 99%.

“This could really change the game. It saves wasted product, reduces wastewater generated from cleaning tanks, and can help make the manufacturing process zero waste,” says Varanasi, who serves as chairman at LiquiGlide.

LiquiGlide works by creating a coating made of a textured solid and liquid lubricant on the container surface. When applied to a container, the lubricant remains infused within the texture. Capillary forces stabilize and allow the liquid to spread on the surface, creating a continuously lubricated surface that any viscous material can slide right down. The company uses a thermodynamic algorithm to determine the combinations of safe solids and liquids depending on the product, whether it’s toothpaste or paint.

The company has built a robotic spraying system that can treat large vats and tanks at manufacturing plants on site. In addition to saving companies millions of dollars in wasted product, LiquiGlide drastically reduces the amount of water needed to regularly clean these containers, which normally have product stuck to the sides.

“Normally when you empty everything out of a tank, you still have residue that needs to be cleaned with a tremendous amount of water. In agrochemicals for example, there are strict regulations about how to deal with the resulting wastewater, which is toxic. All of that can be eliminated with LiquiGlide,” says Varanasi.

While the closure of many manufacturing facilities early in the pandemic slowed down the rollout of CleanTanX pilots at plants, things have picked up in recent months. As manufacturing ramps up both globally and domestically, Varanasi sees a growing need for LiquiGlide’s technologies, especially for liquids like semi-conductor slurry.

Companies like Gradiant, Via Separations, VulcanForms, and LiquiGlide demonstrate that an expansion in manufacturing industries does not need to come at a steep environmental cost. It is possible for manufacturing to be scaled up in asustainable way.

“Manufacturing has always been the backbone of what we do as mechanical engineers. At MIT in particular, there is always a drive to make manufacturing sustainable,” says Evelyn Wang, Ford Professor Engineering and department head. “It’s amazing to see how startups that have an origin in our department are looking at every aspect of the manufacturing process and figuring out how to improve it for the health of our planet.”

As legislation like the CHIPS and Science Act fuels growth in manufacturing, there will be an increased need for startups and companies that develop solutions to mitigate the environmental impact, bringing us closer to a more sustainable future.