The most interesting startup in America is in Massachusetts. You’ve probably never heard of it.

VulcanForms eyes a radical transformation of manufacturing.

DEVENS — About 40 miles northwest of Boston, in a shiny silver building on a long, open road, is a factory.

A most unusual factory.

There is no noisy assembly line. No assembly line at all.

Just a row of tall white machines that hum like servers at a data center.

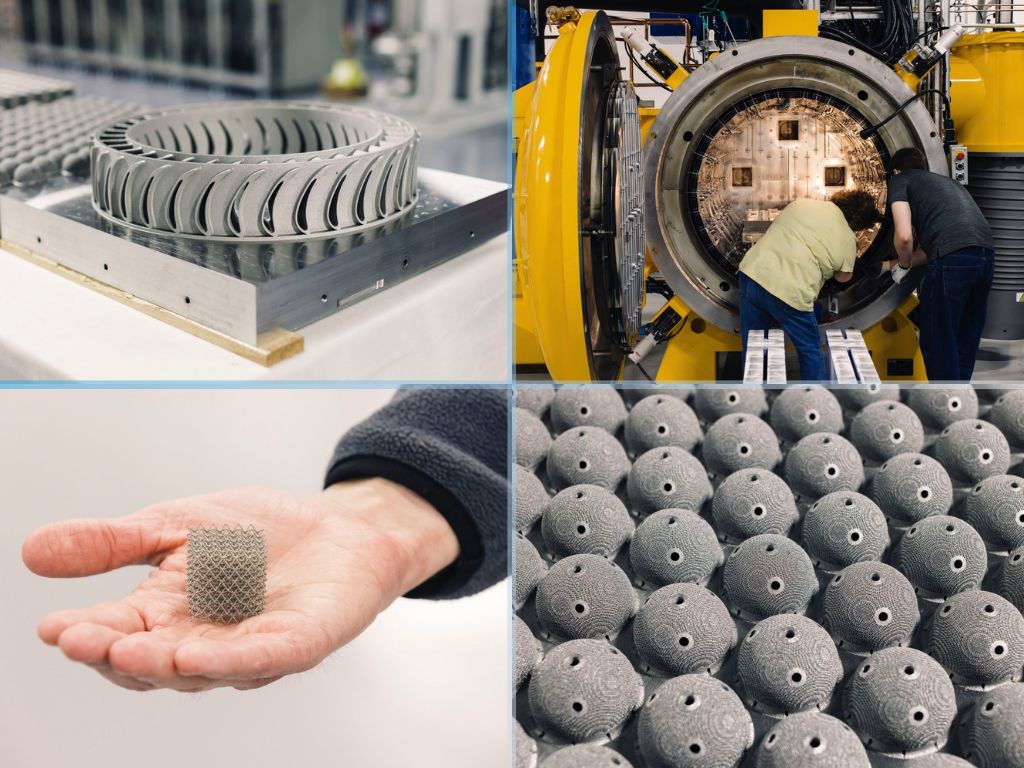

Inside each, a gantry moves swiftly from side to side, training the power of 150 laser beams onto a bed of metallic powder below. The powder melts and solidifies in layers, none thicker than a human hair. And in time, a plate of impossibly intricate parts takes shape.

Hart is a professor of mechanical engineering at MIT and cofounder of the most interesting startup in America.

It’s called VulcanForms. It’s valued at over $1 billion.

And it’s at the leading edge of a push to transform 3-D printing from a niche technology — best known for new-product prototyping and art-class experimentation — into an industrial force.

That won’t replace the cheap, workaday manufacturing that drifted overseas long ago.

But it could help usher in something new — a high-tech industrialism aimed straight at the country’s most pressing problems.

Worried about American reliance on an increasingly hostile China? Building high-end components here could help America break free. Inequality? A return of well-paying manufacturing jobs would ease it. And next-generation 3-D printing could play an important role in slowing climate change, too.

VulcanForms and its competitors are already providing a glimpse of what’s possible; they can make some metal parts with half the energy and a tenth of the materials of a typical factory.

But Hart says that’s just the start.

He’s imagining a time, 20 or 30 years from now, when companies like VulcanForms plug into fusion power or some other entirely green source, tap into an artificial intelligence many times more powerful than what’s available today, and turn out world-beating innovations that can’t even be conceived of now.

“It’s super, super exciting,” he says.

And a little head-spinning, too.

It wasn’t so long ago, after all, that 3-D printing looked like a flop.

In 1945, a pulpy science fiction writer named Murray Leinster published a short story called “Things Pass By.”

It was chock-full of “cosmoquakes” and world-saving heroics.

But it also imagined a curious device Leinster called a “constructor.”

Unlike a standard machine that turned out “one particular part,” the constructor could read designs for just about anything and turn them into “drawings in the air.”

“The process was exactly that of an insect spinning a cocoon, save that the result was no mass of gummed-together threads, but a solid wall of glass-hard plastic, strong as steel, but vastly lighter,” Leinster wrote.

It would take years for reality to catch up with science fiction. But eventually it did.

The cover of "Thrilling Wonder Stories" from 1945. It featured a science fiction story, called “Things Pass By,” that imagined something like a 3-D printer.HANDOUT

Inventors filed patents for the predecessors of today’s 3-D printers in the early 1970s. There were technical improvements in the 1980s. In the late 1990s, researchers at Wake Forest University printed out the building blocks for a human bladder. And in the fall of 2009, the technology seemed ready for its breakout moment.

That’s when Bre Pettis, a charismatic entrepreneur with thick black glasses and a messy mop of hair, took the stage at an event called Ignite NYC and declared the start of a second industrial revolution.

“We have a machine that makes 3-D objects,” he told the crowd, “and it’s freaking awesome.”

His company, MakerBot, was offering up a desktop machine that would bring the power of the factory to the masses. “You get to be the tycoon by making things yourself,” he said. And the press ate it up.

MakerBot was featured in Rolling Stone and The New York Times. And Wired ran a cover photo of Pettis holding one of his glassy printers alongside the headline “This Machine Will Change the World.”

That prediction, though, proved overblown.

Pettis had trouble bringing down the cost of the machines. And the print-at-home market wasn’t nearly as robust as he’d hoped. In 2013, he sold MakerBot and the press moved on. The 3-D printer, it seemed, was destined to be remembered as little more than a novelty.

But even as the technology was fading from the headlines, it was getting traction on the industrial side.

Here it was known as “additive manufacturing,” a reference to the fact that 3-D printers build products from the ground up rather than cutting, milling, or otherwise “subtracting” them from larger pieces of material.

The process allows for complex geometries that typical factories can’t produce, and several large companies were intrigued.

Stryker, a medical technology firm based in Kalamazoo, Mich., prints spinal implants. And GE Aerospace uses the machines to build fuel nozzles for its jet engines; rather than welding together 20 separate pieces, as it once did, the manufacturer prints a single whole part that’s substantially lighter than its predecessor.

Here in Greater Boston, which has emerged as perhaps the most important 3-D printing cluster in the world, several companies have focused on building the machines themselves.

They include Desktop Metal (which is merging with the American-Israeli firm Stratasys), MarkForged, and Formlabs, a $2 billion company on the edge of a Somerville strip mall that makes machines for dental labs and the gaming and entertainment industries. A few years ago, Formlabs printers were used to design the monster in the hit Netflix show “Stranger Things.”

Add it all up and the global market for additive manufacturing was worth some $18 billion last year, according to the consulting firm Wohlers Associates.

That, to be clear, is just a sliver of the worldwide manufacturing market. And the relatively high cost of additive manufacturing will put some limits on growth; materials and equipment tend to cost more than they do in a traditional factory.

But industry leaders and investors say there is reason for optimism.

In the United States, mounting calls for a decoupling from China have ratcheted up interest in domestic manufacturing. And bolstering production here would protect against the sort of supply chain shocks that accompanied the pandemic and the war in Ukraine.

Washington, for its part, is betting big on an industrial transformation.

Congress has poured well over $1 trillion into infrastructure, microchips, and green energy.

Last spring, President Biden traveled to Cincinnati to mark the launch of Additive Manufacturing Forward, a White House-brokered compact among five major companies — GE Aviation (now GE Aerospace), Lockheed Martin, Honeywell, Siemens Energy, and Raytheon Technologies — aimed at encouraging the companies’ smaller US-based suppliers to ramp up additive manufacturing.

Boeing and Northrop Grumman joined the agreement later.

Elisabeth Reynolds, a former special assistant to the president for manufacturing and economic development, says additive will be one of the “foundational technologies” of 21st-century manufacturing, alongside robotics and artificial intelligence.

And she’s putting her money where her mouth is.

She is now a partner at Unless, an investment fund that plans to put $75 million to $100 million per year into companies at the frontier of the new industry.

The technology, she says, is ready to deliver.

“Even five years ago, we weren’t quite at that tipping point,” Reynolds says. “And right now, we are.”

Eclipse provided $2 million in seed funding. And later, it put up an additional $216 million, making it the single largest investor in the startup, which has raised $355 million to date.

VulcanForms’ chief innovation was building machines many times more powerful than the typical 3-D printer — the 150 lasers in the current model dwarf the one or two found in many industrial machines.

The company has used that laser power to build knee and hip implant parts with intricate lattice structures that bone can more easily graft onto, complex computer-cooling devices, and small missile engines.

Until a couple of months ago, there were workers stationed at each machine, monitoring video of these parts as they took shape. But now the data is all funneled to a centralized control room, which will allow for more efficient oversight as VulcanForms adds machines to the factory floor.

By year’s end, if all goes according to plan, the company will be operating the most productive metal additive manufacturing plant in the world.

VulcanForms already supplements its additive manufacturing with precision machining and assembly at a facility in Newburyport. And eventually, the cofounders say, they could imagine an expansion of this additive-plus model in Greater Boston and beyond.

Data and metallic powder travel well.

Hart had just started as a professor at MIT when he decided to teach a course on additive manufacturing.

“Honestly,” he says, it was a chance “to learn about the technology.”

One of his graduate students was a German emigrant named Martin Feldmann who was taken with America’s innovative spirit.

They got to talking about what it would take for the technology to take off, and by the summer of 2015, they’d decided to found a company and draft a patent application for a new kind of 3-D printer.

Feldmann left MIT to build a prototype. And when he’d made enough progress, they went in search of capital.

Greg Reichow, a partner at Eclipse, a Silicon Valley venture capital firm, was intrigued.

At the time, Reichow says, most Valley VCs were obsessed with finding the next social media breakout. But Eclipse saw opportunity in the roughly three-quarters of the global economy that hadn’t been fully transformed by innovation — sectors like health care, logistics, and manufacturing.

Additive manufacturing seemed like a promising way to modernize the factory. And the technology, if impressive in some ways, was ripe for improvement.

Some of the industrial 3-D printers on the market were relatively cheap and reasonably fast but turned out low-quality parts, Reichow says. Others built high-quality parts but moved slowly and were expensive to operate. “The thing that caught our eye about Vulcan,” he says, “is they had come up with a new technique . . . that really allowed you to get all three”: greater speed, lower cost, and higher quality.

What they’re offering, Hart and Feldmann say, is transformative: a software approach to the hardest of hardware.

When “changing a line of code allows you to do something new,” Feldmann says, everything speeds up. Clients can iterate quickly and tweak their products just before going to market, the way tech firms do.

And because VulcanForms is in the United States and not halfway around the world, those clients can pay regular visits to the factory and learn from what they see.

It’s a throwback, in a way, to how America built things before so many of its factories closed down. Design and production were tightly intertwined — feeding off each other and spurring innovation.

VulcanForms is new tech for an old approach. And it’s betting that combination will pay off handsomely.

“The goal is not to build a $2 billion company,” Feldmann says, sitting at a conference table just off the factory floor on a recent afternoon. “We want to build a $100 billion company.”

This article was originally shared by The Boston Globe and written by David Scharfenberg.